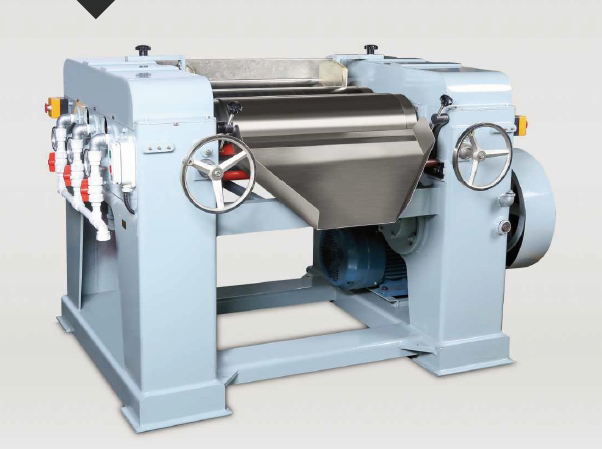

The three-roll mill is primarily used for grinding various slurries such as paints, inks, pigments, and plastics. It is particularly suitable for grinding and dispersing products with high viscosity and fine particle size requirements. The grinding effect is achieved through the surface pressure and differential speed friction of three horizontally arranged specially alloyed rollers.

The improved KS model adopts the latest international chain drive technology, with gears immersed in lubricating oil to maximize the machine's lifespan, reduce noise, and lower energy consumption. All sealing components are imported. The traditional top-adjusting mechanism of the three-roll mill has been upgraded to a gear-driven roller adjustment system, ensuring smoother, more convenient, and long-lasting stable operation.

Customizable temperature display can be installed on the inlet and outlet ports to ensure that product quality is not affected by temperature fluctuations. Additionally, energy-saving devices for cooling water recovery, pressure display mechanisms on the handwheel, or roller heating devices can be added according to customer requirements. The discharge hopper is made of stainless steel, and the exterior is coated with solvent-resistant paint, ensuring the machine's gloss remains unaffected by corrosive solvents.

| Specification | Roller Diameter (mm) | Roller Working Length (mm) | Fast Roller Speed (rpm) | Main Motor Power (kw) | Machine Weight (kg) | Dimensions (mm) | ||

|---|---|---|---|---|---|---|---|---|

| Slow Roller | Middle Roller | Fast Roller | ||||||

| KS5'' | 120 | 280 | 26 | 70 | 186 | 1.5 | 400 | 830x750x920 |

| KS6'' | 150 | 300 | 38 | 87 | 203 | 2.2 | 500 | 1070x880x950 |

| KS8'' | 200 | 600 | 22 | 67 | 200 | 5.5 | 1300 | 1600x1150x1130 |

| KS9'' | 260 | 675 | 27 | 76 | 217 | 7.5 | 2000 | 1800x1400x1180 |

| KS12'' | 305 | 760 | 22.5 | 70 | 217 | 11 | 2800 | 1980x1540x1230 |

| KS16'' | 406 | 810 | 19 | 58 | 178 | 15 | 4300 | 2050x1810x1500 |

| KS16''L | 406 | 1000 | 19 | 58 | 178 | 22 | 5000 | 2250x1810x1500 |

2 Year

2 Year

KS Powerful Three Ro

KS Powerful Three Ro

KS Strengthen Three

KS Strengthen Three

KS Heating Three Rol

KS Heating Three Rol

KS Hydraulic Two(Fou

KS Hydraulic Two(Fou

KS New Strengthen Th

KS New Strengthen Th

KS-S Three Roll Mill

KS-S Three Roll Mill

KS Three Roll Mill

KS Three Roll Mill

KS Vertical Three Ro

KS Vertical Three Ro